The Cyclone 3d was developed as an Oxygen-15 "workhorse". It is capable of accelerating deuterons up to around 3.4MeV and produces Oxygen-15 using the

14-N(d,n)15-O

nuclear reaction. The production of this cyclotron was limited to 4 near-prototype models being released, and they are no longer supported by IBA. This particular one was taken from the Institute of Neurology, Queen Square, London around 2005.

Other PET centres which use Cyclone 3d are:

Turku PET Centre, Turku, Finland

GE Imanet, Hammersmith, London, England

Rudolf-Virchow-Krankenhaus, Berlin, Germany

Because of the prototype nature of these cyclotrons, there are many differences between each machine, so experience gained on one Cyclone does not necessarily translate 100% to another.

Cyclone 3d uses a PIG type internal ion source, and accelerates the ions in 1.8T magnetic field. RF power is around 10kW, operating in the first harmonic mode.

Extraction from the tank is by means of an electrostatic deflector, which pulls the ions into the fringe of the magnetic field. Here, the beam is radially defocussed and strikes titanium target foil 10cm long. The foil is 7.5micron thick, so the beam loses around 0.4MeV in it's crossing.

Target gas is passed via a compressor through the target body and over the target foil. This method also doubles as foil cooling.

The control system is provided by a Siemens Step 5 Programmable Logic Controller, with a simple HMI for switching on the various power supplies and setting parameters manually. The HMI runs on Windows 3 operating system. A future project would be to upgrade the control system to something more modern, as well as adding extras that were overlooked during the original manufacture of this machine.

The Cyclone 3d at the WBIC occupies the same vault as the GE PETtrace. Due to the workload on the PETtrace, time spent working on the Cyclone has been limited.

A period of time was spent developing and optimising the cyclotron and gas delivery system for our application. Our delivery system currently allows gas to flow to Addenbrooke's Hospital's PET-CT scanner where it is used with a Hidex water generator. A future project will be to integrate with the gas processing system of the PETtrace, to deliver O-15 to the WBIC's PET scanner. With regards to the optimization of the cycloton, we have developed tools to aid us in this, such as an Axial Beam Profiler, which consists of 8 tungsten rods placed between the beam collimator and the target foil. The currents picked up by these rods are amplifed and fed into a A-D converter board which, via USB, gives an visual display of the distribution of the beam entering the target. Another useful tool during setup of the cyclotron have been a collection of highly calibrated Beam Location Strips which can be placed inside the cyclotron in order to locate any lost beam.

A period of time was spent developing and optimising the cyclotron and gas delivery system for our application. Our delivery system currently allows gas to flow to Addenbrooke's Hospital's PET-CT scanner where it is used with a Hidex water generator. A future project will be to integrate with the gas processing system of the PETtrace, to deliver O-15 to the WBIC's PET scanner. With regards to the optimization of the cycloton, we have developed tools to aid us in this, such as an Axial Beam Profiler, which consists of 8 tungsten rods placed between the beam collimator and the target foil. The currents picked up by these rods are amplifed and fed into a A-D converter board which, via USB, gives an visual display of the distribution of the beam entering the target. Another useful tool during setup of the cyclotron have been a collection of highly calibrated Beam Location Strips which can be placed inside the cyclotron in order to locate any lost beam.

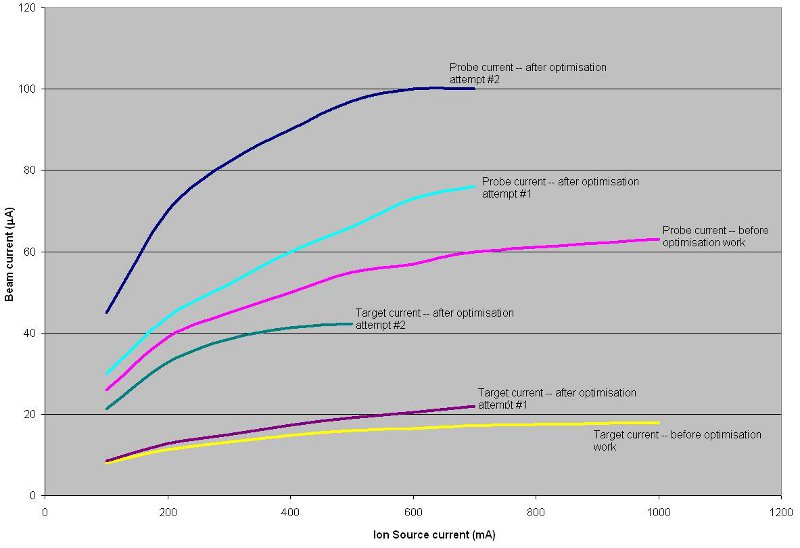

The beam intensity, as measured on the internal diagnostic probe, was nearly doubled from its initial intensity. This has been achieved by tweaking centre region parameters (dee positions and ion source to puller distance) and by adjusting the peak RF voltage. After the inital dee position set up, we had an beam intensity of 39uA measured on the probe for 200mA of ion source current. After the RF voltage increase, achieved by altering the RF tube's anode power supply voltage, we have achieved 70uA on the probe for 200mA of ion source current. The probe is positioned near the extraction radius, so this current should represent the intensity of the beam entering the electrostatic deflector. Before deflector tuning (electric field strength, position and electrode to septum distance), the target current measured was 22.5uA for 200mA of ion source current, representing an extraction efficiency of just over 30%.

The beam intensity, as measured on the internal diagnostic probe, was nearly doubled from its initial intensity. This has been achieved by tweaking centre region parameters (dee positions and ion source to puller distance) and by adjusting the peak RF voltage. After the inital dee position set up, we had an beam intensity of 39uA measured on the probe for 200mA of ion source current. After the RF voltage increase, achieved by altering the RF tube's anode power supply voltage, we have achieved 70uA on the probe for 200mA of ion source current. The probe is positioned near the extraction radius, so this current should represent the intensity of the beam entering the electrostatic deflector. Before deflector tuning (electric field strength, position and electrode to septum distance), the target current measured was 22.5uA for 200mA of ion source current, representing an extraction efficiency of just over 30%.

The above graph shows the progress of the beam optimisation. The pink, cyan, and blue traces show the intensity of the beam picked up by the diagnostic probe against varying ion source current, recorded after a warm-up period of around half an hour, and where the pink trace was "as found", blue trace is "as left". The yellow, violet and brown traces show the intensity of the beam striking the target (before deflector optimisation), also recorded after a warm-up period of around half an hour. Yellow trace is "as found", brown trace is "as left".

Several successful test runs were carried out and yield information collected. The test setup consisted of mixing the 15-O target gas and a 5% hydrogen in Nitrogen gas, with each line having a separate mass flow controller. The gas mixture was sent to the WBIC PET scanner room's Hidex water generator, where a water bolus with an activity of 600MBq was made. The optimum gas flow out of the target was found empirically by monitoring the peak activity arriving at the scanner room, and was found to be around 460ml/min. The gas flow along the 5% hydrogen line was adjusted to give an approximately stochiometric mix for water production.

A separate test was carried out to measure the activity yield of the target. The activity out of the target was measured in a coil of volume 10ml placed in a Capintec dose calibrator, located about 30m from the Cycloton (in the PET scanner room). The activity measured here was around 0.1MBq/ml uA. This value is consistent with other Cyclone 3 cyclotrons.1,2

References:

1. D. B. Mackay, et al "Quality assurance for PET gas production using the Cyclone 3D oxygen-15 generator", Applied Radiation and Isotopes, October 1999.

2. H. Sipila, Personal Correspondance, Turku PET centre.